First drive since the 70s

- Frank Donslund

- Sep 23, 2025

- 4 min read

Updated: Sep 29, 2025

The Mini 1000 is born

The classic Mini was in production for 41 years and was facelifted 7 times.

The first major update came in the autumn of 1967, and thus it became, in the best English tradition, the Mark II. The updates were not insignificant. Most importantly, the 1000 Super version got the slightly larger engine (998). At the same time, the "remote" retracted gearshift from the Cooper versions became standard in the Mini 1000. Unfortunately with a de-tuned engine 1000 engine with 38 hp. The Cooper's disc brakes were also not included in the purchase. A slightly larger front grille and larger rear lights were part of the cosmetic changes. The model was available as both Morris and Austin.

But it was still a significant update of the rather basic Mini. The Mark II model was only in production for 2 years and is therefore quite rare today. My brother had 2, a '68 and a '69, and we got around a lot in them. There was free speed in Denmark at the time, so most trips were with a brick on the accelerator.

Our Austin Mini 1000

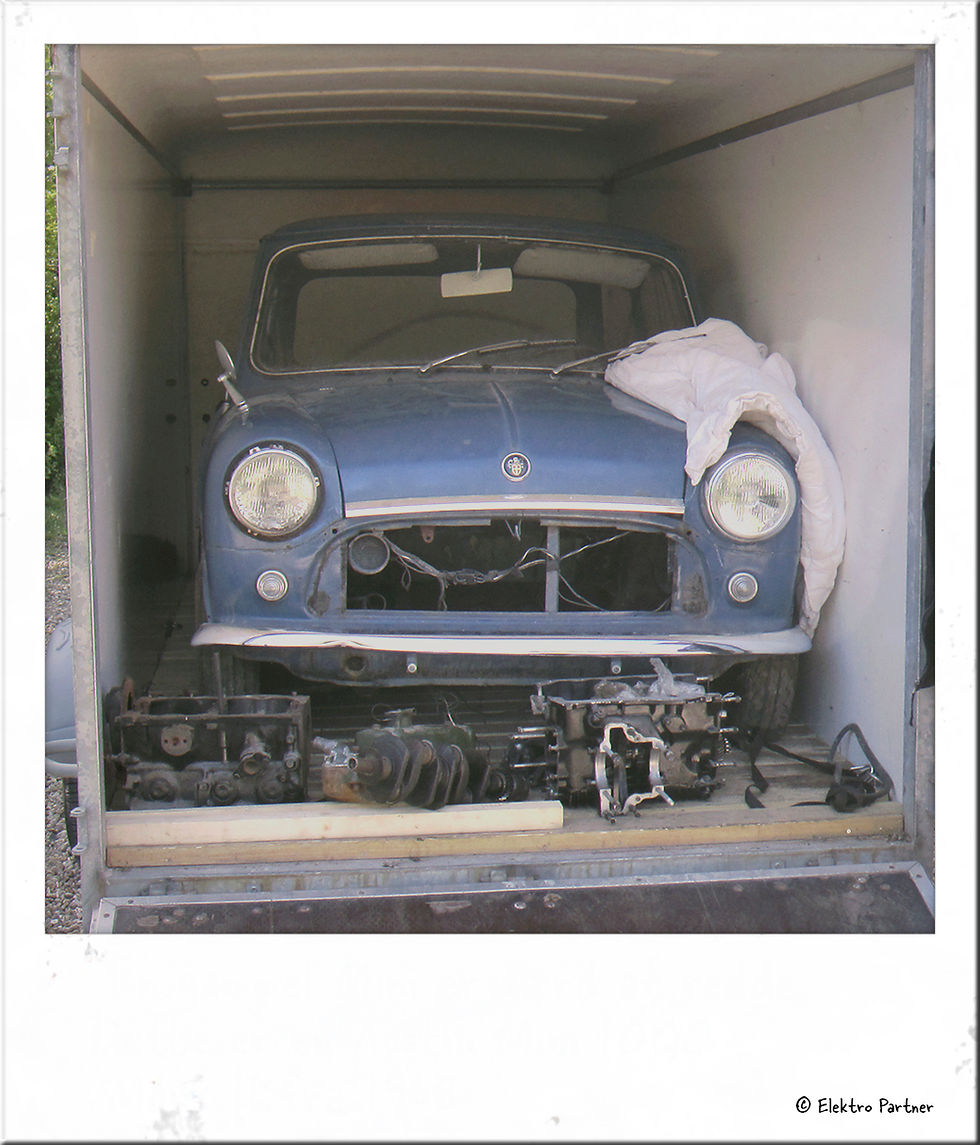

In 2011 I came across an ad for a 1968 Mark II for sale in Sweden. It was in the way and needed to be gone as soon as possible. It was in a garage that needed to be dismantled, and it had been there for decades. It wasn't quite complete, and the engine had been taken out, and several parts for it had been lost. I told my good friend Johnny that his little blue Mini 1000 was for sale cheaply a little north of Gothenburg. He had had one of these as his first car. He begged and picked it up. Unfortunately, Johnny only managed to take it apart before he got sick. His untimely death put a temporary stop to its renovation. 2 days before Jonny died, he asked me to take care of the Mini, and that's a commitment.

I already had a nice Mrk. I, from 1966, so I didn't need more and didn't have the space. But a Mini doesn't take up much space, so I took on the challenge.

A bound task

I picked it up on a bitterly cold winter day in 2017, and I honestly didn't know what to do with it. So it ended up in a barn at driving instructor Preben Rasmussen in Ikast. I had neither the time nor the energy to fix it. But I kept an eye on the missing parts.

I find a complete engine and gearbox in North Jutland. Over a year, the engine and gearbox are renovated with new pistons, crankshaft balanced, as well as a Cooper cylinder head. All wear parts are replaced with new quality parts, e.g. some NOS original parts. The engine is started up in a test bench and placed as an ornament at Elektro Partner's Nostalgia Corner, waiting for a car that is worthy of it.

Corona changes everything

The Corona epidemic is changing the lives of many - there is a little time to spare. I manage to find the car's registration certificate, and the car has value, and I get approval from SKAT so that it can be registered in this country. The driving instructor's farm is put up for sale, so the empty body will be picked up in early spring 2020 and moved around a bit, where there was now space, and eventually end up at a workshop in Hejnsvig, which would take care of the last rust. The body will be blasted with dry ice, something I have never tried before. There was rust everywhere, so that's why. New original front fenders are coming, and the rust and small dents are slowly getting under control.

Elektro Partner and Gunnar take over the project

The raw bodywork reveals everything, but the car is very real, and the bottom plate with the chassis number is intact. I start to see that it could make a really nice Mini out of it, and I choose the best red color (tartan red), now that the boring blue paint has blown off, inside and out. We are now at 2021. This is where the car's savior comes into the picture. Gunnar Iversen. He is an Elektro Partner handyman and coincidentally a trained mechanic at Nielsen and Aarestrup, which was then Morris in Grindsted, and Gunnar takes on the task of assembling the car.

It will be until 2022 before the car is back in the workshop for the final minor adjustments to the bodywork. Painting takes time, and it will be really good. In the summer of 2023 we will pick up the car and assembly can begin.

My parts from previous projects come in handy

I had used the waiting time to find the missing parts, such as the front axle and a new rear axle. However, we choose to give it a "dry" undercarriage. The associated parts are procured, and the undercarriage is prepared for assembly. The original hydrolastic suspension elements were in too poor condition. It takes time, and many of the small parts that were in my own stock of Mini parts are prepared for assembly. I have stored some parts for decades, for example a completely complete interior for a Mark II in black. A tailgate that fits a '68 is also found, and Bent Fasterholdt (Billund) straightens it out and welds a new bottom piece. A bit of an art. All the pieces for the big puzzle are now ready.

The car is assembled with a great deal of patience with vintage-correct parts, apart from Cooper-specific engine upgrades and disc brakes. What a difference the extra 17 hp makes to the pulling power.

Over a period of 8 months, the car is assembled piece by piece, and on January 17, 2025, the car drives the first meters under its own power, and on February 5, it is completely assembled. Some trips to test drives to fix various small things happen over the spring and summer. The old Mini has been reborn after decades in a mothball. Johnny would have been proud of the result.

Der kom ikke nummerplader på den i 2025, men det sker nok i det nye år.

Comments